What is water transfer printing?

Water Transfer Printing technology, also known as Cubic transfer technology (Cubic Transfer), it is used Water-soluble film (PVA film) to carry graphics, and water is used as a dissolving medium to transfer color patterns to other objects.

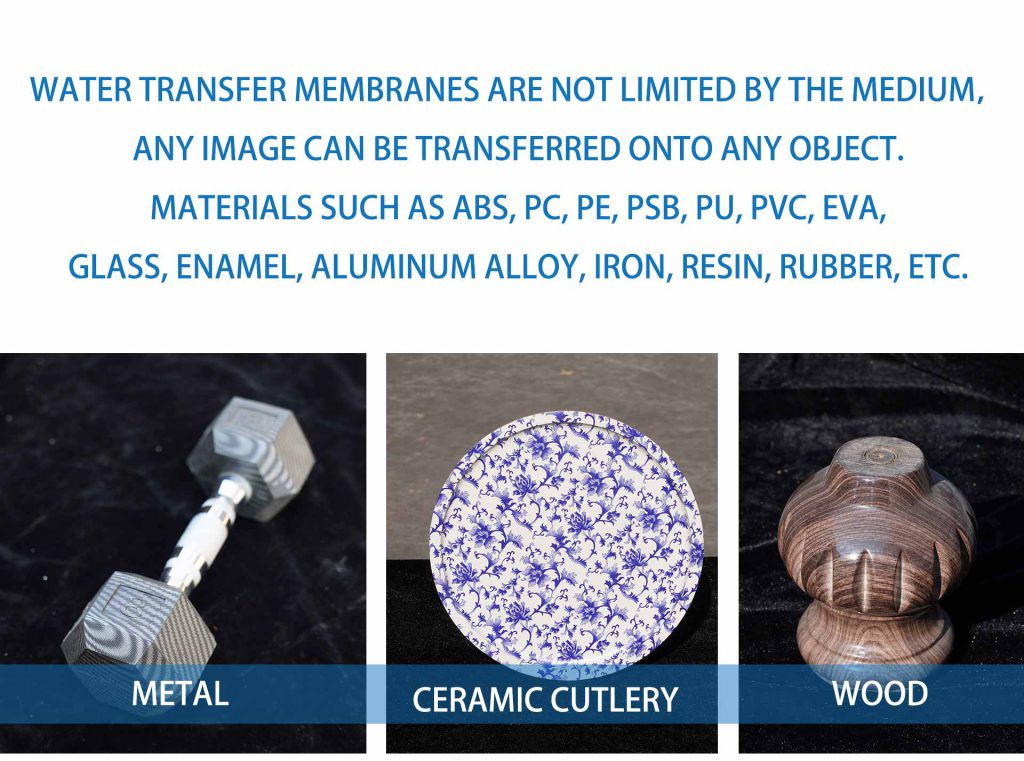

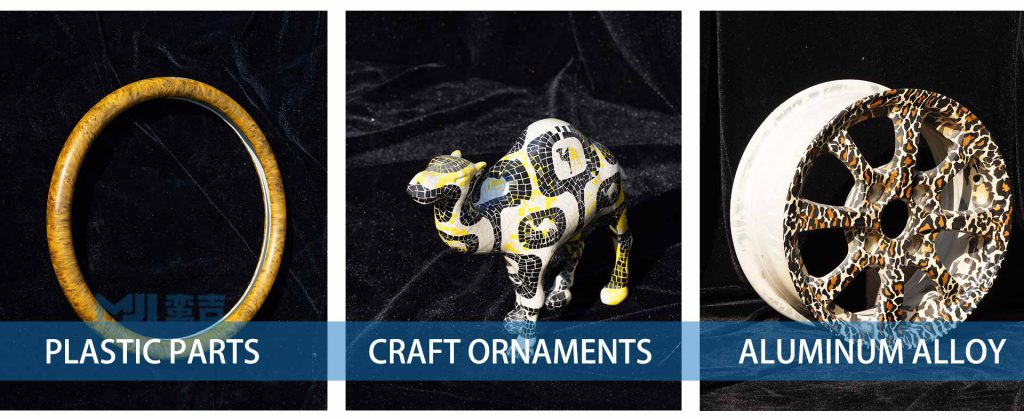

Because water transfer film tension is excellent, it is easy to wrap around the surface of the product to form a graphic layer, and the surface of the product is like spray paint to get a completely different appearance. Can be transferred to any shape of the item, for manufacturers to solve the problem of three-dimensional (3D) product printing.

Most of the materials we see in our daily life are suitable for Water Transfer Printing, such as glass, metal, ceramics, plastics, wood products, silicone and so on. Many factories through theWater Transfer Printing technology to make their products look unique, have resolution, products are competitive in the market, expand their market, and massively increase the sales volume.

The operation steps of the water transfer printing

- 1. Prepare the object to be transferred—Clean dust or impurities.

- 2. Base coating (Pre-Coating, use spray booth machine)—Match base lacquer obtaining suitable color.

- 3. Dry base primer/lacque—After lacquer, dry it by oven or drying line.

- 4. Hydrographics film selection— Cut film that suits work piece size from a roll.

- 5. Film Extension (Manual Hand Putting/Automatic rolling Dipping Tank )

- 6. Activation (Manual/Automatic Spray)—Spray activator on the film uniformly

- 7. Transfer (Manual/Automatic dipping)—Object goes into the water at an angle of 10°- 45° (depends on the shape and size).

- 8. Washing—Flash the object just transferred with tap water till no sticky feeling by hand.

- 9. Drying—The object have to be dehydrated by oven (Or dry it naturally)

- 10. Top Coating ( Spray PU clear coat )— Increase their weather abilities.

- 11. Dry clear coat—Dry PU varnish for 30 minutes by oven, then wait 24-hour natural drying until being packed.

- 12. Packing:—Each finished product is individually packed in plastic bags and then in cartons.

Actual application effect of water transfer in various industries

This is a new business opportunity,seize it!

I hope you can develop other more exciting products with water transfer printing technology.